product description

Fuji Electric specializes in manufacturing "FJHKCN" brand vehicle-mounted sliding vane air compressors used in new energy vehicles and rail transit industries. The installed power is 1.1-37Kw and the displacement is 0.16-6m3/min. It has passed the ISO90001-2015 quality management system. Products are widely used in new energy buses, new energy logistics vehicles, new energy special vehicles, transportation rail industry, automobile maintenance industry, scientific research institution laboratories, etc.

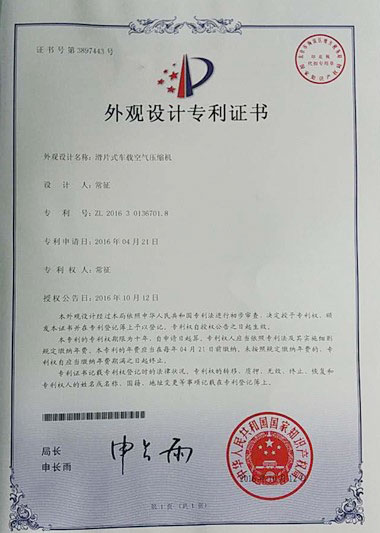

| Over the years, the company has devoted itself to the research and development of in-vehicle products, insisted on continuous improvement and innovation, combined with the needs of the domestic new energy vehicle market, has achieved great scientific research results in the design, production and performance optimization of the machine, and obtained a number of patents. Compared with other similar products in the market, it has the characteristics of the smallest volume, the lightest weight, the lowest cost, and the longest life. Fuji Electric's integrity, strength and product quality have been recognized by the industry, providing customers with the best compressed air system solutions. Friends from all walks of life are welcome to visit, guide and negotiate business. |

Example model | KZ222 |

Displacement | 0.25 m3/min |

Work rate | 2.2 kW |

Working pressure | 1.2MPa |

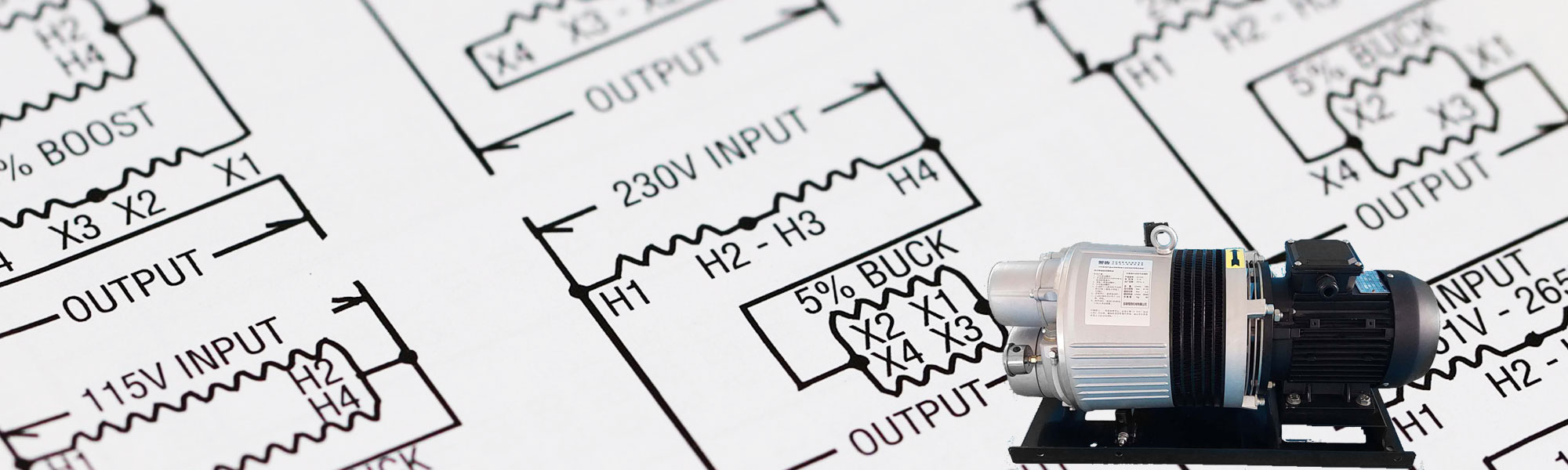

Product feature one: Appearance patent design, simple and exquisite appearance; The machine head adopts integrated design, there are no pipes and joints on the periphery, and there are few faulty nodes, which greatly improves the reliability of the product. It can provide users with stable, 24 hours a day, 365 days a year. Efficient and continuous air power. At present, the product with the simplest appearance, smallest volume, lightest weight and most stable operation on the market. |  |

| Product feature two: The efficiency is stable, the gas production is consistent, and it remains stable throughout the year; the exhaust does not pulsate; the sliding vane rotates with the eccentric rotor, and under the action of centrifugal force, it pops up and rotates with the inner wall of the spindle (there is a lubricant film in the middle). Internal compression, the space between the sliding vanes will continue to become smaller, and the gas will be continuously compressed. When the sliding vane is pressed down by the cavity for the shortest time, an exhaust port is set, and the compressed air will be discharged from here to complete the air compression. process. |

Product feature three: The inside of the machine is a multi-stage labyrinth design. Before the compressed gas enters the oil and gas separator, it passes through a set flow angle. Through the principle of beading, 99% of the liquid oil in the oil and gas mixture is filtered out, which reduces the processing load of the oil and gas separator core and extends the oil content. The service life of the core. |  Patent application is in progress! |

| * The fins are casted at one time to prevent differences in gas flow due to different angles of artificial installation. Other manufacturers use screws to reduce casting costs. |

Product feature four:

The filter area of the newly designed oil separator element (compared to similar filter elements) has been increased by 60%, the service life can reach 8000-10000 hours, and the highest filtration accuracy can reach 1ppm;

● Original imported from Italy

● Hierarchical filtration, classified filtration, using more than three filter materials

● Adopting a newly designed pleated process to increase the filter area by 50%

Product feature five:

A temperature-controlled bypass valve with low temperature protection is provided as standard, which can be customized according to the actual operating temperature of the machine, and the range is between 75 and 88°C.

Description: When the lubricating oil temperature is below 75℃, the lubricating oil directly returns to the oil cavity to make the lubricating oil temperature rise rapidly; when the temperature reaches 75℃ or higher, the lubricating oil enters the heat exchanger for cooling; this prevents the low temperature running time of the lubricating oil Excessive length will cause emulsification, and can avoid high-temperature tripping failures, and ensure that the machine runs within a reasonable temperature range; when the lubricating oil temperature exceeds 110°C, a protective shutdown is performed through the temperature sensor

Product feature six: The simplest and direct transmission structure ● Coupling drive ● Transmission ratio 1:1 ● The highest transmission efficiency, the least loss ● Longest service life of moving parts ● The most ideal component optimized structure reduces the number of components |  |

Patented technology is only for function description | Product feature seven: The new shutdown and unloading system with patented invention breaks through the original longest unloading time of the machine from 1 minute and 50 seconds to less than 5 seconds, ensuring fast and safe unloading of the machine, and avoiding the machine's internal pressure from starting with load and causing motor failure And shorten the life; at the same time, reduce the probability of oil emulsification caused by the deposition of gaseous water molecules in the compressed air into the lubricating oil. |

Product feature eight: The specially developed special oil for sliding vane air compressors, and the anti-emulsification test of special lubricants has passed the ASTM D140 test. The product has: ● Strong anti-wear protection ability ● Strong anti-rust ability ● Good anti-emulsification performance ● Low carbon deposit tendency ● Two kinds of special oils: 2000 hours of mineral oil and 5000 hours of synthetic oil |  |

Applications

|

|

|

|

bus | Heavy Truck | Special vehicles | Rail vehicle |

product category

KZ series | KY series |

Asynchronous motor | Permanent magnet synchronous motor |

Power: 1.5 kW 2.2 kW 3.0 kW | |

615*270*300mm | 595*270*300mm |

40--42Kg | 38--40Kg |

|

|

Car sliding vane air compressor

Water immersion test

The first stage of the experiment

Step 1 The water tank contains enough water to immerse the machine;

Step 2 According to the requirements of the motor manufacturer, soak the motor for 30 minutes;

Step 3 Synchronize the host to soak in water

Step 4 After the water is discharged, let it dry naturally for 2 hours (ambient temperature 17-25℃, sunny)

Step 5 Assemble the machine and start it up

The second stage of the experiment

Step 1 The water tank contains enough water to immerse the machine;

Step 2 Exceed the requirements of the motor manufacturer, do the motor soak in water for 48 hours;

Step 3 Synchronize the host to soak in water

Step 4 After the water is discharged, let it dry naturally for 2 hours (ambient temperature 18-25℃, sunny)

Step 5 After the machine is assembled, open the air cover and no water seepage is found

Step 6 Power on and it runs normally!